Unsupervised models in Predictive Maintenance

Written by Marketing

4 December 2023 | Predictive Maintenance | Article

Transforming Predictive Maintenance: Unsupervised Models for Anomaly Detection with MonoM

Predictive Maintenance (PdM) has long become an essential component for many industries seeking to maximize the availability and efficiency of their assets. One of the key challenges in PdM is the early detection of anomalies, a critical step in preventing failures and unplanned downtime. In this context, unsupervised models play a fundamental role, and in the MonoM platform, these are at the heart of this transformation.

What are Unsupervised Models?

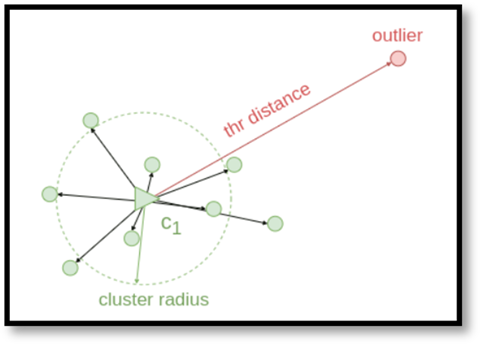

Unsupervised models are a category of machine learning techniques that do not require labels or previously classified training data. Instead, they rely on identifying unusual patterns and behaviors within unsupervised data. This approach is particularly valuable in situations where anomalies are unknown or change over time.

Predictive Maintenance Anomaly Detection

Anomaly detection in Predictive Maintenance seeks to identify unexpected changes in asset behavior. These changes can be signs of impending problems, such as an increase in vibration of a machine or a decrease in the efficiency of a system. The ability to identify these early signs is crucial to schedule maintenance before a failure occurs.

Unsupervised Models in MonoM

MonoM, has incorporated unsupervised models into its product to effectively address this challenge. Through the combination of sensor data, process data and the power of artificial intelligence, MonoM enables organizations to implement intelligent anomaly detection strategies.

How do we do it?

Inputs & Preprocessing

Initial data processing to remove outliers and aggregate data, allowing the user to select a data period in which the asset is operating correctly.

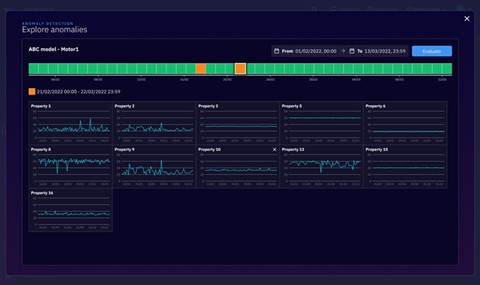

Anomaly detection

Training of a model capable of identifying anomalies in the ingested data for a given asset in an agnostic way. This model does not need prior history, although you can use it if it will exist and it adapts to any set of variables and magnitudes.

In addition, it does not require expert knowledge to use it, it only requires an initial configuration where it is parameterized: data intervals to be analyzed and a time window in which the data will be divided for subsequent inference.

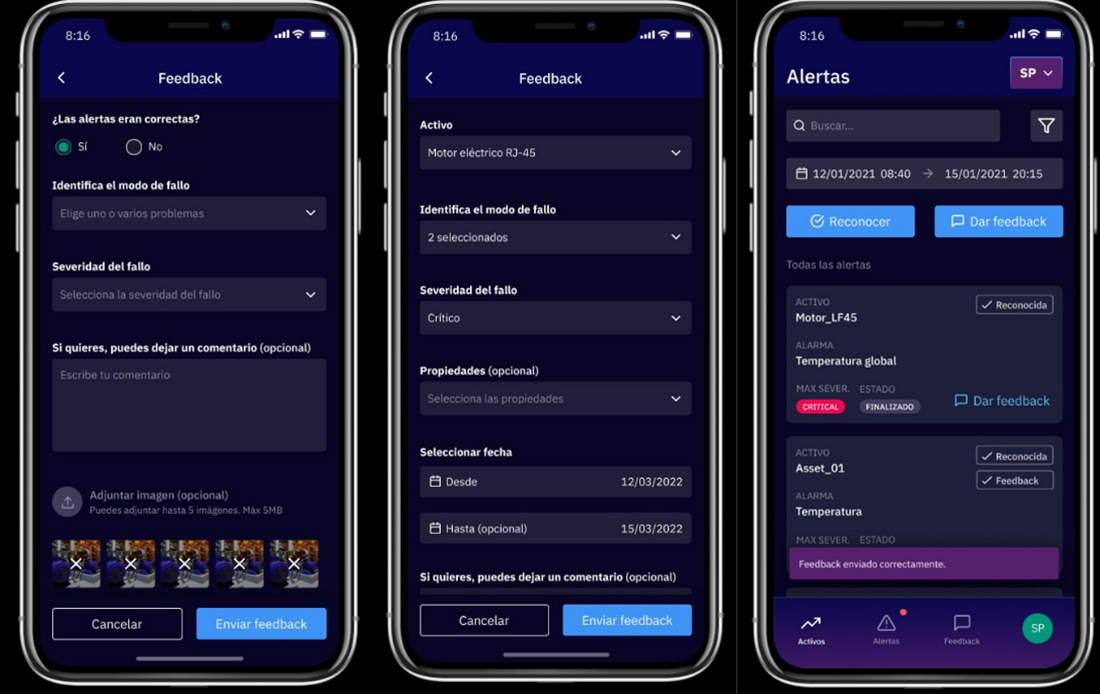

Based on the new data ingested and the feedback provided by the user, the algorithm learns continuously.

Classification of anomalies

Algorithm capable of performing anomaly classification based on: expert knowledge of analysts, ISOs and user feedback. These algorithms learn over time to identify more precisely the type of anomaly.

Benefits of Unsupervised Models in MonoM

Early Detection

The unsupervised models in MonoM enable early detection of anomalies by identifying subtle patterns that may indicate impending problems. This gives companies the opportunity to take preventive action before costly failures occur.

Flexibility

Unsupervised models are highly adaptable and can detect a wide variety of anomalies, even those previously unknown. This is essential in industrial environments where anomaly patterns can evolve over time.

3. Cost Reduction

Proactive anomaly detection and data-driven maintenance scheduling lead to lower operating costs by avoiding emergency repairs and reducing unplanned downtime.

4. Increased Efficiency

By maximizing asset efficiency and avoiding downtime, organizations can increase their productivity by increasing their overall performance.

Use Cases

Unsupervised models in MonoM have proven their worth in a variety of industrial applications. Some notable examples include:

Machinery Monitoring: By analyzing machine vibration data to prevent failures.

Product Quality: Identify anomalies in production processes that may affect product quality.

The Future of Predictive Maintenance with MonoM

The integration of unsupervised models into the MonoM platform marks an important milestone in Predictive Maintenance. By harnessing the power of artificial intelligence and machine learning, organizations can anticipate problems and keep their operations running more efficiently than ever before.

In a world where prevention is the key to avoiding costly production downtime, unsupervised models are the perfect tool for process anomaly detection, quality improvement and to increase overall efficiency in Predictive Maintenance.

Conclusion

Unsupervised models are an essential component in the evolution of Predictive Maintenance, and MonoM is at the forefront of this revolution. By identifying unusual patterns and anomalous behavior in data, organizations can take preventative action, reduce costs and maximize the efficiency of their operations. At MonoM, the future of Predictive Maintenance is now.

Unsupervised models are an essential component in the evolution of Predictive Maintenance, and MonoM is at the forefront of this revolution. By identifying unusual patterns and anomalous behavior in data, organizations can take preventative action, reduce costs and maximize the efficiency of their operations. At MonoM, the future of Predictive Maintenance is now.