Enabling technologies for Industry 4.0: IoT, big data and artificial intelligence

Written by Marketing

October 17, 2024 | The importance of continuous monitoring in predictive maintenance | Article

Industry 4.0 enabling technologies: IoT, big data and artificial intelligence, among others.

In the current era of Industry 4.0, digitization and automation are redefining industrial processes, increasing efficiency and productivity very significantly. Behind this revolution are a series ofenabling technologies that act as fundamental pillars for the development and correct implementation of this new way of working and producing.

From the Internet of Things (IoT) to Artificial Intelligence (AI), these technologies are transforming industrial environments and opening up a world of possibilities. In this article, we will discuss some of the key enabling technologies of Industry 4.0 and their impact on production and business management.

Internet of Things (IoT)

The Internet of Things is one of the most important technologies in Industry 4.0. It consists of connecting devices, sensors and machines to the internet, enabling real-time data collection and communication between different systems. It allows companies to remotely monitor and control their equipment, optimize operational efficiency and proactively prevent failures. In addition, IoT facilitates the creation of intelligent production systems and the implementation of data-driven services, such as predictive maintenance and inventory management.

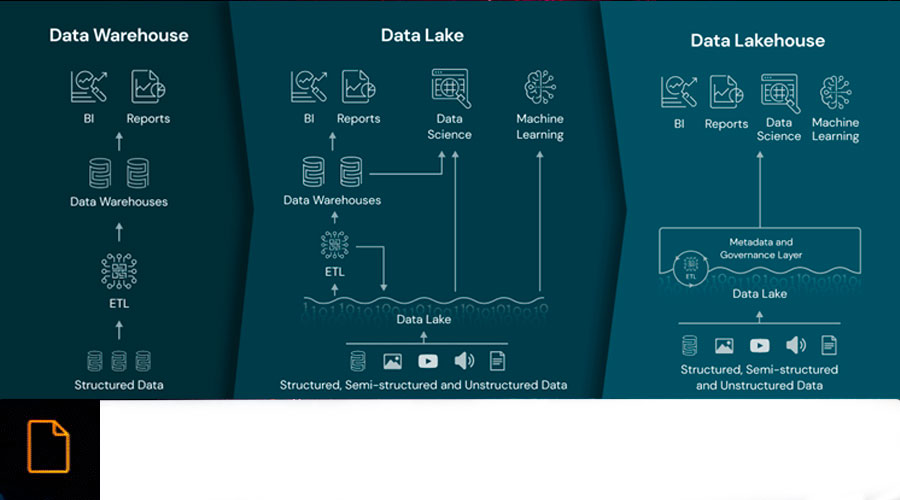

Big data and advanced analytics

Big Data refers to the analysis of large volumes of data to extract valuable information and make informed decisions. In Industry 4.0, data collection and analysis are essential to optimize production processes, identify behavioral patterns and predict future trends. Advanced analytics, which includes techniques such as machine learning and artificial intelligence, enables companies to make the most of their data and gain deep insights into their business. In this way, they can improve quality, reduce costs and increase efficiency in all areas of the company.

Artificial Intelligence (AI)

AI is another key enabling technology for Industry 4.0. It enables machines to perform tasks that would normally require human intervention, such as pattern recognition, natural language processing and autonomous decision making. In the industrial context, AI is used to optimize processes, improve product quality and increase workplace safety . For example, computer vision systems can inspect product quality in real time, identifying defects and reducing waste.

Augmented reality (AR)

Augmented Reality combines the physical world with the digital world, superimposing real-time virtual information on the physical environment. In Industry 4.0, AR is used to enhance employee training and education, facilitate the completion of complex tasks, and improve efficiency in the workplace. For example, workers can wear smart glasses with AR capabilities.

Blockchain

The blockchain is a distributed recording technology that enables the secure storage and transmission of data in a decentralized manner. In Industry 4.0, blockchain is used to improve transparency and traceability in the supply chain, ensure product authenticity, and simplify auditing and compliance processes. In addition, blockchain facilitates the creation of smart contracts, which are autonomous computer programs that automatically execute the terms of a contract when certain predefined conditions are met.

These are some of the key enabling technologies, which are transforming the industry, the way companies operate and are opening up new opportunities for innovation and growth. From IoT to artificial intelligence, these technologies are driving the digitization and automation of industrial processes, improving efficiency, quality and competitiveness in an increasingly demanding global marketplace.

At MonoM we work with these technologies to transform the industry. Discover on our website how we can help your company, and the different applications of the technologies according to the different industrial sectors.

Sources:

https://telefonicatech.com/blog/digitalizacion-industrial-revelamos-las-claves-en-advanced-factories

https://www.pwc.es/es/digital/industry-40.html

https://universidadeuropea.com/resources/media/documents/01_SteamUE_AlbertoSolsRZX.pdf