ARTIFICIAL INTELLIGENCE OF THINGS (AIoT) FOR INDUSTRY 4.0

Written by Antonio Ramírez

12 Sept 2022 | Artificial Intelligence | IoT | Article

You may be as surprised as I was by the concept of AIoT, as when I found out that "AI", in addition to Artificial Intelligent, means "love" in Japanese.

AIoT is the fusion of technology capable of collecting, sending and receiving data from or to a device, with technology capable of interpreting such data, intelligently and autonomously, and execute actions from the same device or from other systems, using artificial intelligence based on a cloud platform.

In the AIoT market there are well-known names such as Watson from IBM, or Bosch and others less known, such as Mediateka general purpose AIoT company. But if we talk about AIoT for Industry 4.0then we have to talk about MonoM.

AIoT TECHNOLOGIES

Surely you intuitively know that the technologies that make up AIoT are Artificial Intelligence and IoT. However, it is important to point out that both have special characteristics when we talk about AIoT applied to Industry 4.0. Just as the IoT has to be very specific, since it is not the same as the one used to control the vibrations of an engine as the one used to monitor the oil pressure, AI also requires different sub-technologies that guarantee not only that from all the data received the appropriate ones are chosen for each monitored device individually, but also that they can apply the learning of specialized analysts using from machine learning with its models to expert systems that include the topography, not of each model, but of each equipment, to name a few.

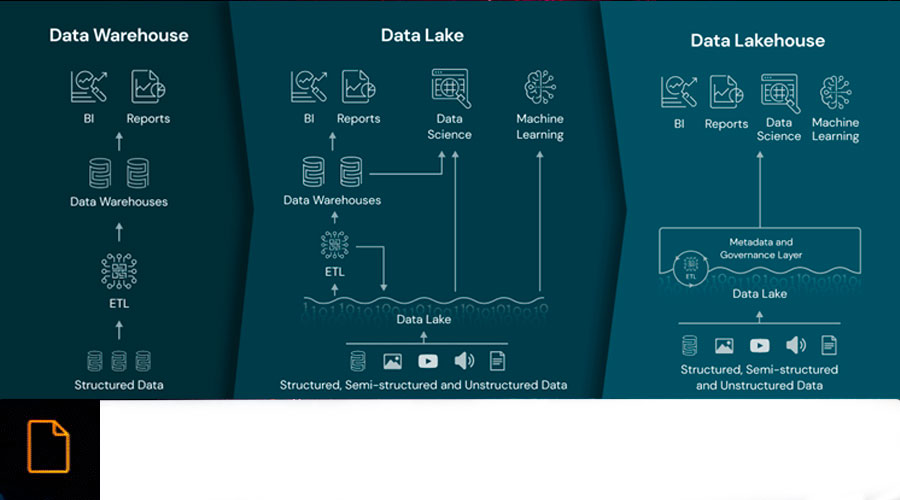

But you cannot forget two technologies that are pillars for AIoT. One is Big Data with which we can store huge amounts of data, whether structured(Warehouse) or unstructured(Data Lakes) to be analyzed by AI. Without this data processing technology, it would be impossible to manage all the data that IoT is capable of providing. You only have to think that the projection for 2030 is more than 29 million IoT devices according to Statista, and imagine the data per second that these devices can transmit and you will begin to understand the huge amounts we are talking about. And we are just getting started.

Nor forget 5G, as another of the pillar technologies for AIoT, since such a huge amount of data and the need to execute actions in real time demands a communication speed, much higher than the current one. However, in the industrial world you can see 4G solutions, even 3G, wifi or wired Sensoric that to date is allowing AIoT to advance in the industry by leaps and bounds.

AIoT INDUSTRIES

For this section I have to turn to the experience of MonoM, which has been ratified by IOT ANALYTICS, during this year 2022, with its recognition as one of the first industrial IoT cloud platform companies in the world.

The first industry where AIoT has begun to spread has been the manufacturing industry and its need for predictive maintenance in all its machinery, allowing not only automated predictive maintenance, or the detection of anomalies in assets, but also the integration of IT, IoT and OT data, or the internal traceability of the finished product, among many others.

However, as I said, manufacturing has only been the first one, since others have followed, such as Oil& Gas, Wind, Solar, Automotive, Defense, Civil Engineering or Foof&Beverage.

The growing need for water management and treatment, given the increasing scarcity of this resource, has made this the latest sector in which AIoT is succeeding, and helping to automate water level, leak detection, water quality control, digitization of domestic meters and others.

AIoT BENEFITS IN INDUSTRY 4.0

If I had to choose just one, I would have to choose between automation or digitization of an industry's assets. After all, that is the final benefit that is obtained when we apply AIoT to it.

It is clear that real-time device monitoring enables more efficient and productive decision making, but this would not be possible without other benefits such as democratization of asset utilization, predictive maintenance automation, productivity control and risk management to avoid production lines or assets that break down or start working defectively.

And we cannot forget the immense information it provides us with that can be used for better studies and analysis, nor the business aspect, with the possibility of selling finished products incorporating AIoT to customers, thus being able to offer them better services and even new services that improve competitiveness and sales.

It is clear that AIoT has become a key Deep Tech technology for Industry 4.0. We will remain expectant with its evolution and especially in an area that perhaps another day we can talk about it. I am talking about Digital Twins.

Have a happy and prosperous day.

Antonio Ramirez - CMO MonoM (Alava Group)